With over 120 years of ceramic manufacturing experience, we remain committed to producing specialized ceramic solutions that solve customer problems. Our expert engineers will lead you through every step of our superior manufacturing process, from raw powder preparation to post-firing machining, to ensure that your product will be of the highest quality and will be delivered on time.

- Aerospace & Defense

- Analytical Instrumentation

- Ceramic Industry Partners

- Energy

- Industrial Equipment

- Industrial Products

- Oil & Gas / Petrochemical

- Semiconductor Processing

- Transportation

Ceramics Manufacturing Services

Because ceramics employ many different types of manufacturing processes, we want to help you understand them, the following is a basic outline. It will give you a good idea of what it takes to manufacture ceramic parts. It is important to note that all ceramics start as granular powder made up of a base material such as Alumina or Zirconia, mixed with other stabilizers and binders that give each “ceramic body” its own unique characteristics.

Powder Preparation Understanding how raw powder contributes to the final properties of fired ceramics is key to providing components that meet the challenges of your application.

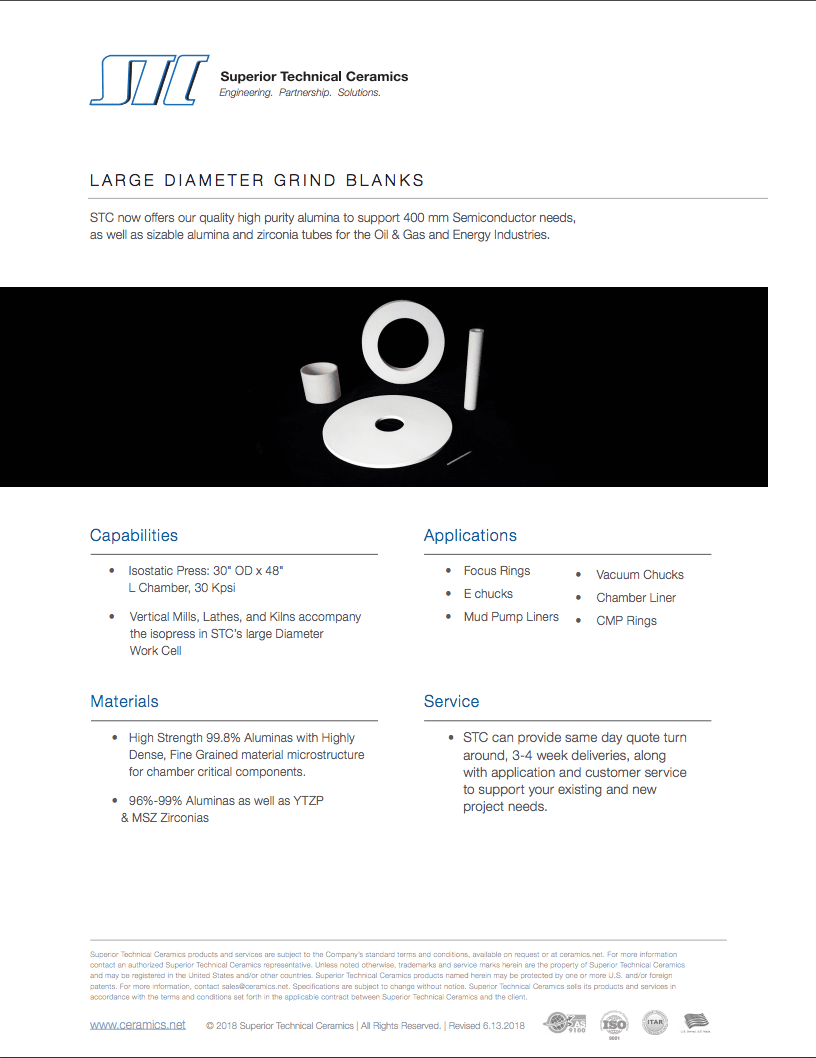

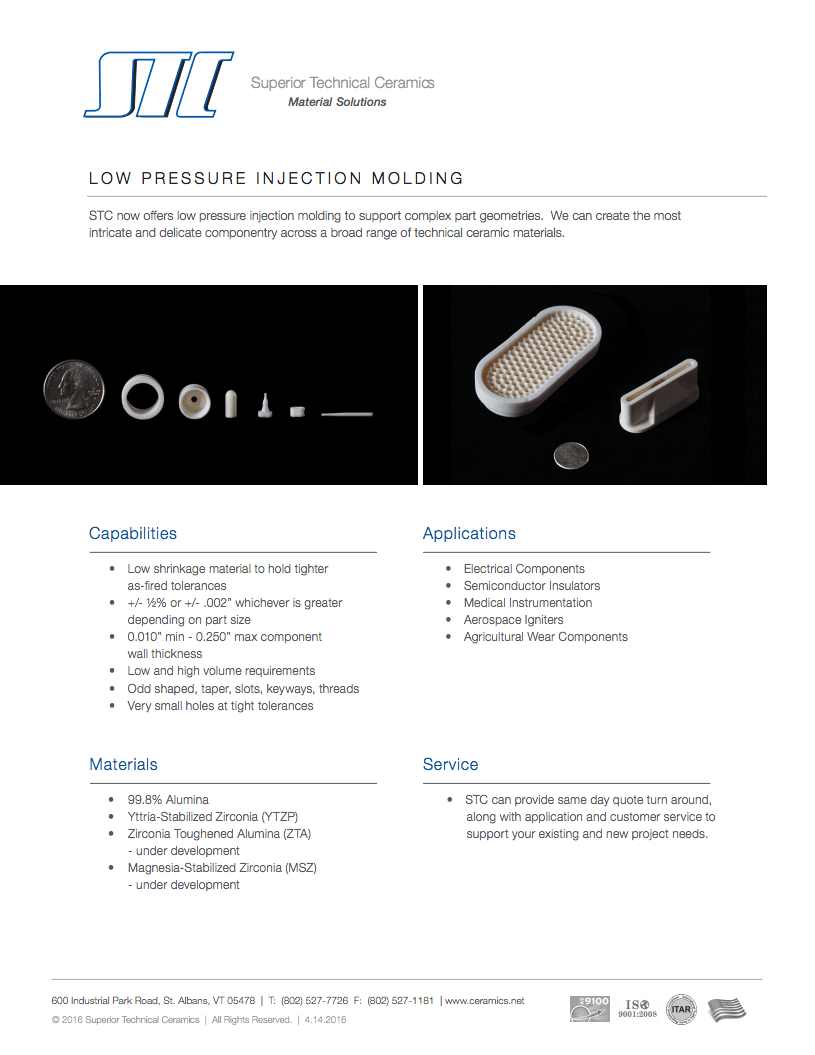

Forming There are several basic forming methods such as Isostatic Pressing, Extrusion, Injection Molding, Mechanical Pressing.

Green Machining The machining of a ceramic in the unfired state is called green machining. Green machining of ceramics is done whenever possible since the machining of ceramics after firing is very costly.

Firing In order for ceramic to be hard and dense, they must be “sintered”, or fired to high temperatures for prolonged periods of time in gas or electric kilns.

Coating / Glazing One of the reasons that parts are glazed is to make it easy to remove unwanted residue. For instance, spark plugs are glazed to reduce areas of potential arcing in high voltage environments.

Grinding & Cleaning Grinding and cleaning are part of the after firing operations, please find detailed descriptions for each process at the link above.

Metalizing & Plating We produce thick film metalization inks that utilize a Moly-Manganese (MoMn) refractory formulation designed for oxide ceramic bodies to provide one of the industry’s strongest bond strengths.